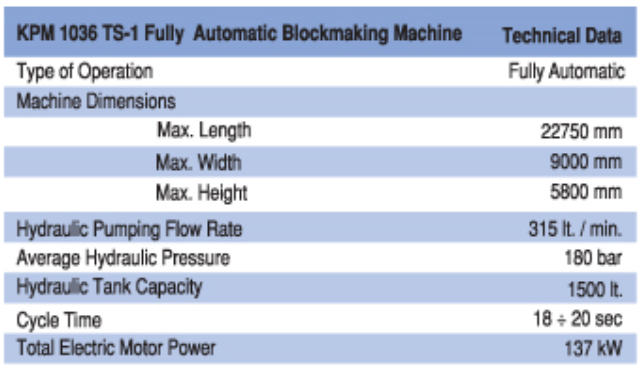

KPM 1036 TS

It is a fixed single-layer production machine.

Production quality is high and cycle time is short.

Outer mold locking is provided by pneumatic bellows cylinders. By this way, a smooth vibration propagation is achieved in the mold.

Vibrator motors are operated through a frequency-controlled speed drive. By this way, the frequency and strength of the vibration can be adjusted by the control panel according to the type of stone.

Rational valves are used in all important movements.

Stationary and single layer machine.

Product quality is heigh and cycle period is short.

The locking of the outern mould is being carried out by means of pneumatic cylinder.

For this reason an unchanging vibration on the mould is being ensured.

Vibrator motors are being driven via a frequence controlled speed driver. So that the vibration frequence and speed are adjusted via control panel according to the stone's shape.

By means of transfer & collecting robot the products are stacked onto delivery pallet.

The types of KPM 1036 TS-2 are manufactured with finger-car system